Introduction to Robotic Arms in Manufacturing

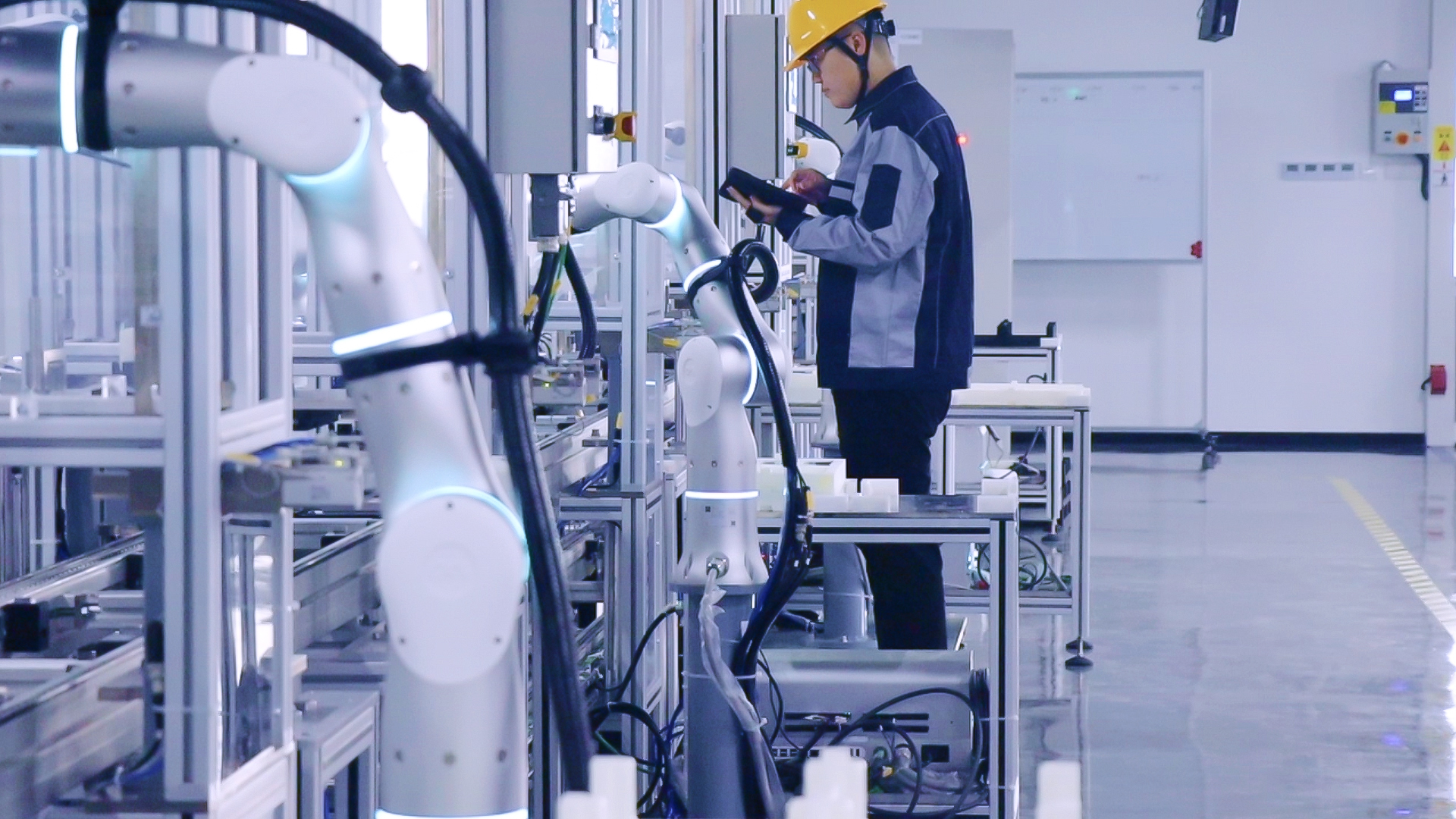

In modern manufacturing, robotic arms have become essential tools for enhancing productivity and quality. These automated systems, like Flexiv's adaptive robots, seamlessly combine industrial-grade force control with artificial intelligence to perform complex tasks with remarkable consistency. From automotive and electronics to pharmaceuticals and food processing, industries worldwide have embraced robotic automation to maintain competitiveness, reduce costs, and improve product quality in increasingly demanding markets.

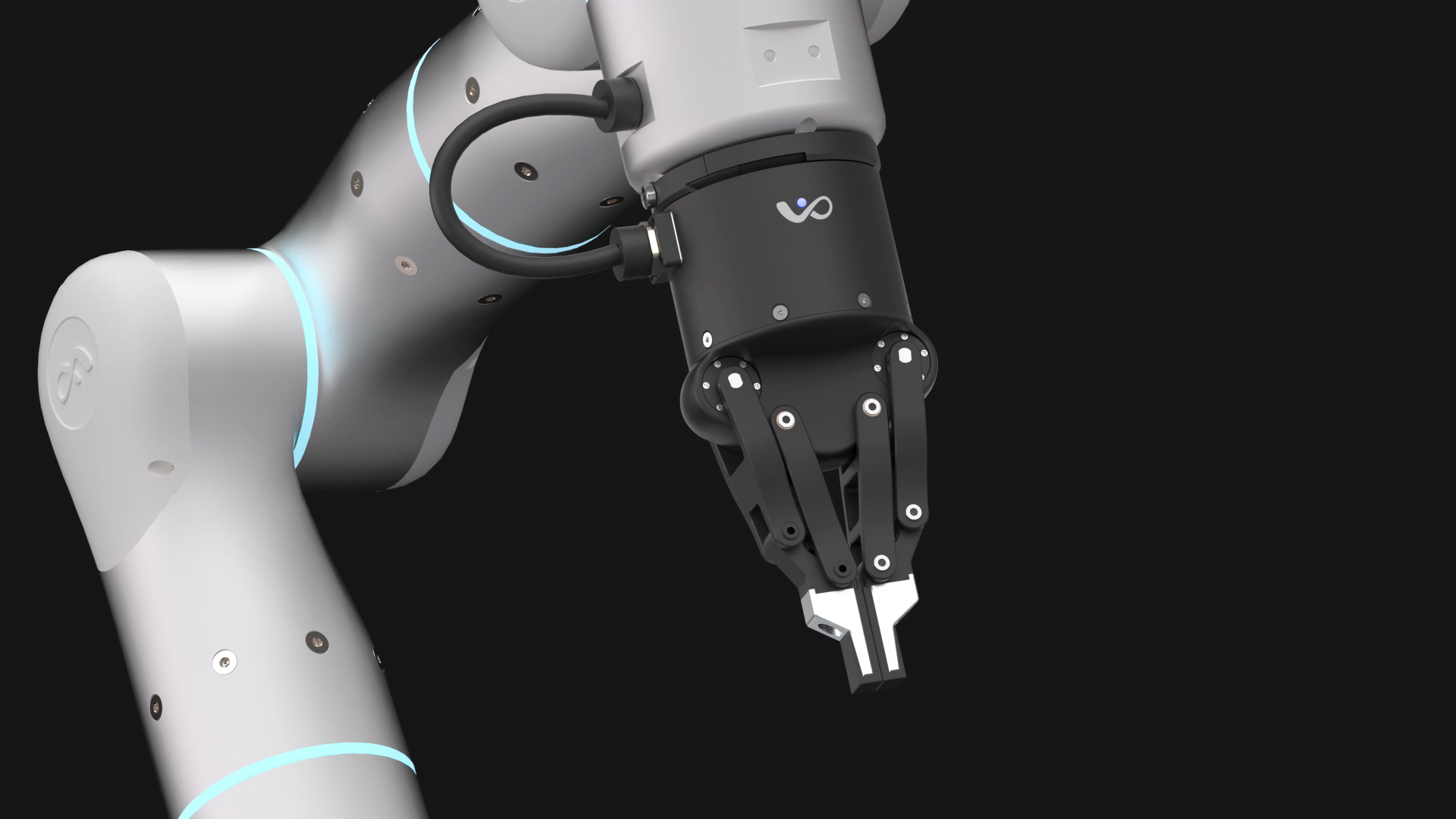

Key Components of Robotic Arms

A robotic arm consists of several vital elements working in harmony. The base ensures operational stability while housing dedicated, model-specific independent controller systems, as revised while joints connected by links enable precise movement throughout the robot's workspace. End effectors—essentially the "hands" of the robot—are specialized for specific tasks, ranging from Flexiv's versatile robotic arm grippers to polishing grinders and common suckers.

Actuators power the robot's movements, typically using servo motors capable of sub-millimeter precision. These work alongside various sensors that provide crucial environmental feedback about visual, position and force information. The robot's controller processes this data to coordinate movements according to programmed instructions. Flexiv's proprietary control algorithms enable our adaptive robots to respond intelligently to their environments, adjusting in real-time to workpiece variations.

Common Manufacturing Applications of Robotic Arms

Robotic arms excel in diverse manufacturing applications. In assembly operations, they rapidly and precisely fit components together, whether inserting electronic parts into circuit boards or assembling complex mechanical devices. Surface treatment applications benefit from robots' ability to maintain perfect torch angles and speeds across different paths, liberating people from toxic dust environments.

Material handling robots efficiently transport items throughout the manufacturing process, from loading raw materials to organizing finished products. Quality control has been transformed by vision-equipped robotic arms that inspect products with unwavering attention to detail, detecting defects invisible to the human eye. Flexiv's adaptive robots enhance these capabilities by incorporating force sensitivity and hierarchical intelligence to handle variations without reprogramming.

Advantages of Using Robotic Arms in Manufacturing

The implementation of the robotic arm offers numerous advantages. Increased efficiency comes from continuous operation without breaks or fatigue, with many Flexiv customers reporting substantial improvements in cycle time efficiency. Enhanced quality is achieved through both positional accuracy, measured in fractions of a millimeter, and precise force control capabilities, ensuring consistent output across millions of repetitions.

Flexibility has become crucial in modern manufacturing, with robotic systems being quickly reprogrammed for different tasks. Flexiv's adaptive robots feature intuitive programming interfaces and can learn new tasks through easy demonstration. Safety improvements represent another key benefit, as robots take over dangerous tasks involving extreme temperatures or heavy lifting, significantly reducing workplace injuries.

Future Trends in Robotic Arms for Manufacturing

The evolution of manufacturing robotics continues rapidly. Embedded intelligence enables robots to optimize movements and improve performance through experience. The CE&ETL-certified adaptive robots designed to work alongside humans create new possibilities for collaboration without extensive safety infrastructure.

Secondly, advances in sensor technology expand robotic capabilities with enhanced vision systems and tactile feedback mechanisms. Finally, customization and scalability are becoming increasingly important as manufacturers seek modular, adaptive production lines that can be reconfigured as manufacturing needs evolve—an approach emphasized by Flexiv's easily reprogrammable robots.

At Flexiv, we're committed to pushing the boundaries of robotic manufacturing with our adaptive robots that combine precision with human-like adaptability and intelligence. For manufacturers looking to gain a competitive edge, implementing these advanced robotic solutions is essential for maximizing productivity, quality, and return on investment.