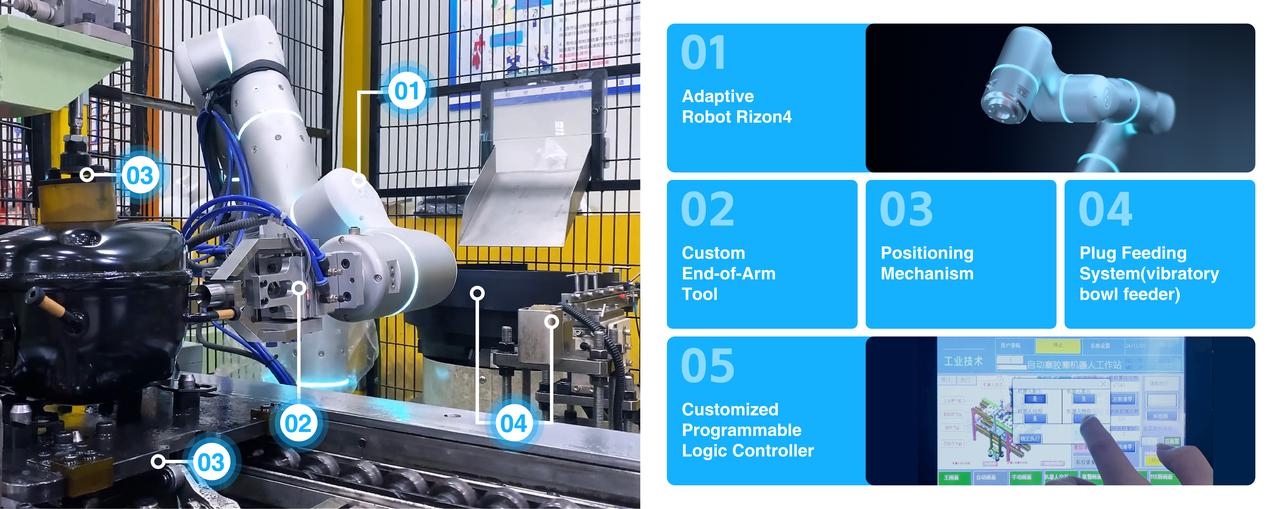

Automated Tube Plugging Solution for Compressors

At a Glance

• Customer: An industry leading compressor manufacturer (subject to an NDA).

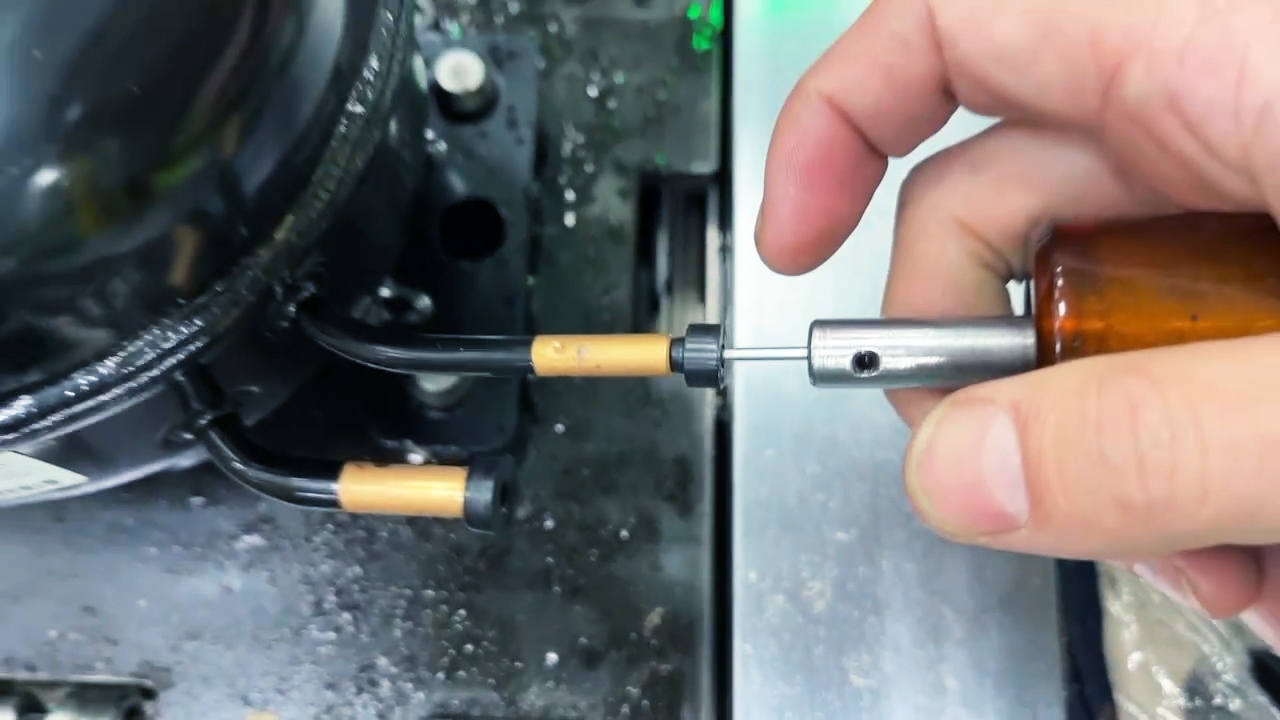

• Problem: During compressor production, the copper tubes used for discharge, charging, and suction must be plugged to prevent oil leakage.

• Solution: Flexiv developed a fully automated tube plugging solution powered by the Rizon 4 adaptive robot. Using advanced force sensing, it replicates the precision and care of manual plug insertion.

• Key Features: Automatic compensation for workpiece variation, human-like force-controlled insertion, integrated failure detection, and real-time data monitoring.

Advantages

• Supports multiple compressor models and five plug types.

• Compensates for up to ±5 degrees of tube deviation.

• Enables quick line changeovers in under three minutes.

• Reduces cycle times while improving quality and throughput.

Customer Profile

The client’s production line handles several compressor models, each requiring different rubber plug types. During production, each plug must be slightly deformed to fit securely into the copper tubes, a task traditionally performed by skilled operators. Because the tube positions varied, automating the process with traditional robotic solutions was found to be impossible.

Flexiv’s Solution

Equipped with real-time force sensing and hybrid force/motion control, Flexiv’s adaptive robots can accurately replicate the manual plug insertion process.

Through an intuitive drag-and-drop teaching interface, operators can perform line changeovers in under three minutes without programming experience.

The result is a smarter, faster, and more flexible approach to compressor production that ensures consistency, precision, and repeatability across every unit.

Solution Advantages

High Tolerance for Angular Deviation

Flexiv’s automated plugging solution compensates for up to ±5 degrees of tube deviation, ensuring rapid and precise plug insertion without impacting cycle time.

Autonomous Force Monitoring

With industry-leading force sensitivity, the Rizon 4 can detect when a plug is at risk of puncture or deformation, even when fitted with multi-kilogram end-of-arm tools.

Human-Like Force-Controlled Insertion

When insertion resistance is detected, the robot automatically activates a hybrid force/position control, replicating the nuanced motion of manual insertion for consistent and reliable results.

Quick Training & Effortless Setup

With no prior robotics experience required, operators can be fully trained to use the solution in less than thirty minutes. This reduces downtime, maximizes productivity, and enables staff to move into supervisory positions.

Exceptional Flexibility

Flexiv’s solution supports multiple compressor models and five plug types. With drag-to-teach programming, a quick-change end-of-arm flange, and a touchscreen PLC with an adjustable insertion force from 15 to 100N, the system can be easily adapted to new compressor models or line adjustments.

Retrofit-Friendly

Designed with integration in mind, Flexiv’s compact solution can be installed into existing production lines without layout modifications, making it ideal for both new and legacy facilities.

Why Choose Flexiv?

Our robots fuse advanced force control and artificial intelligence to achieve unparalleled industrial efficiency. Simple to use, ultra-reliable, and requiring no barriers, our automation solutions don’t just replicate manual labor, they exceed it.