Automated Pre-Delivery Vehicle Inspection

At a Glance

Customer: A leading electric vehicle manufacturer (NIO).

Problem: Before leaving the factory, every vehicle must undergo a series of rigorous inspections to ensure it is fully functional and ready for delivery to the end customer. Traditionally, this manual process was time-consuming, labour-intensive, and susceptible to human variability.

Solution: Flexiv deployed two Rizon 10 adaptive robots, integrated with visible-light and thermal vision modules and an AI-powered self-inspection system, to automate seat inspection, interior trim verification, and charging capacity testing. The result is consistent, high-quality inspection at significantly higher speed.

Key Features: Advanced force and compliant motion control, thermal imaging inspection, intelligent interior inspection, mixed-model compatibility, and data-driven manufacturing.

Overview

To enhance production quality, consistency, and efficiency, NIO partnered with Flexiv to fully automate its vehicle quality assurance process. Flexiv’s adaptive robots now validate charging functionality, seat operation, and interior components with 100% precision and repeatability. By automating what was once a manual process, inspection efficiency has increased while quality standards have been elevated.

Flexiv’s Solution

HOW IT WORKS

-

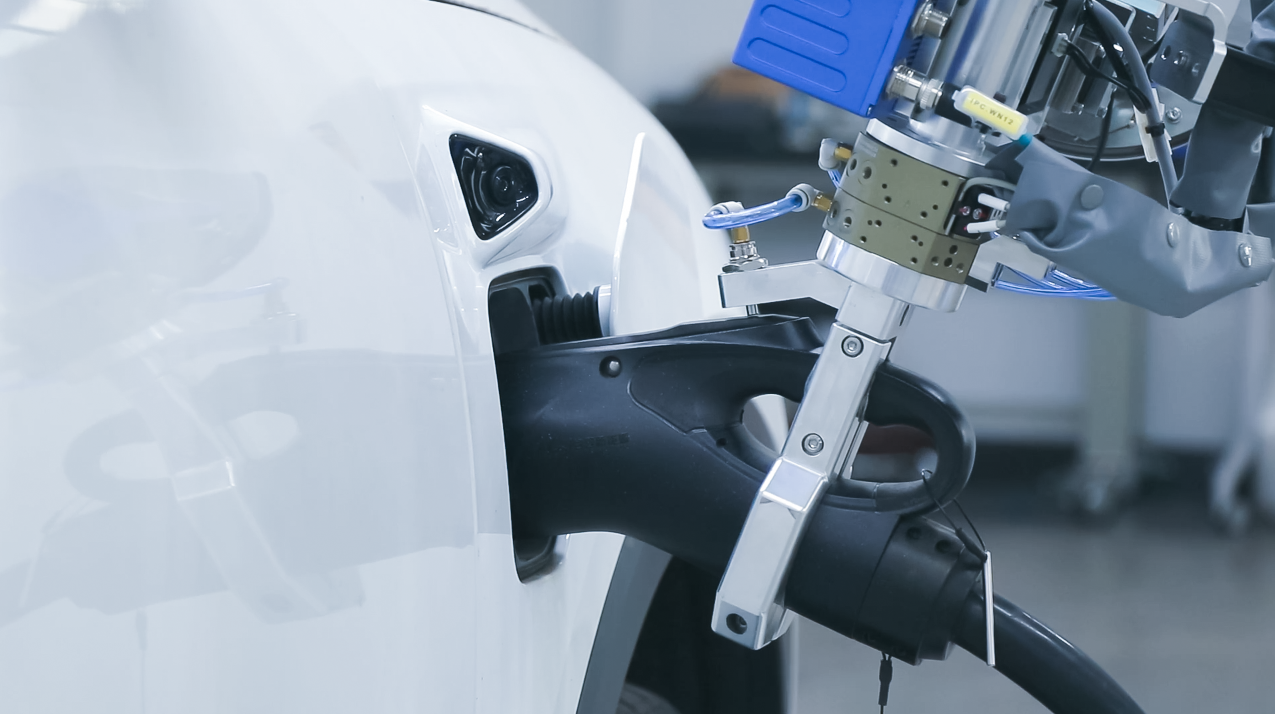

Tool Selection & Coarse Visual Positioning

The EV model is automatically identified, and the appropriate charging plug is selected. Using coarse visual positioning, the robot moves the plug to the vicinity of the charging port.

-

Compliant Insertion & Charging

Through a combination of force control strategies and compliant motion, the robot inserts the charging plug in a manner that closely replicates human handling. Once connected, the charging current test is initiated and evaluated.

-

Thermal Imaging Verification

A robot-mounted thermal camera verifies the performance of heated comfort features installed in the vehicle. Any abnormality or failure is automatically detected and flagged by the AI inspection system.

-

Intelligent Interior Inspection

By combining computer vision with smart inspection algorithms, the system evaluates seat leather quality, colour consistency, stitching accuracy, and infotainment system configuration to ensure compliance with customer requirements.

Project Advantages

-

Significantly Improved Inspection Speed

Three major inspection steps are completed in just 84 seconds, delivering a 48 percent efficiency improvement over manual inspection.

-

Inspection Accuracy Beyond Human Capability

Advanced force control and vision algorithms prevent damage to charging ports caused by improper connector handling and eliminate common human inspection oversights.

-

Universal Compatibility for Mixed-Model Production

Two robots perform simultaneous inspection tasks across mixed production lines. Force control combined with quick-change tooling enables seamless compatibility across six vehicle models and four charging configurations.

-

Data-Driven Intelligent Manufacturing

Robot-generated inspection data is fully traceable and integrated into NIO’s proprietary self-inspection platform. This enables continuous process optimisation and supports the development of next-generation intelligent factories.